From metering to IIoT:

make your offer 200% stronger

Industries need integrated systems to solve their problems and tasks

Get Demo

why

Improve manufacturing with digitalization and automation

Power supply reliability and observability

Know your energy sector facilities is the best way to manage it

Analyze power consumption and losses

Reduce losses and energy part in production costs

Reduce number of

shutdowns and downtime

shutdowns and downtime

Decrease time of reaction on failures from 2 hour to 2 minutes

Find ways

for optimizations

for optimizations

Discover new sources of optimization with data

50,2 %

saved from downtimes

see the IKEA case

60x

less time to react

see the AZOT case

420

warnings about changes in process

see the Darkhan TPP case

what we do

Solutions

-

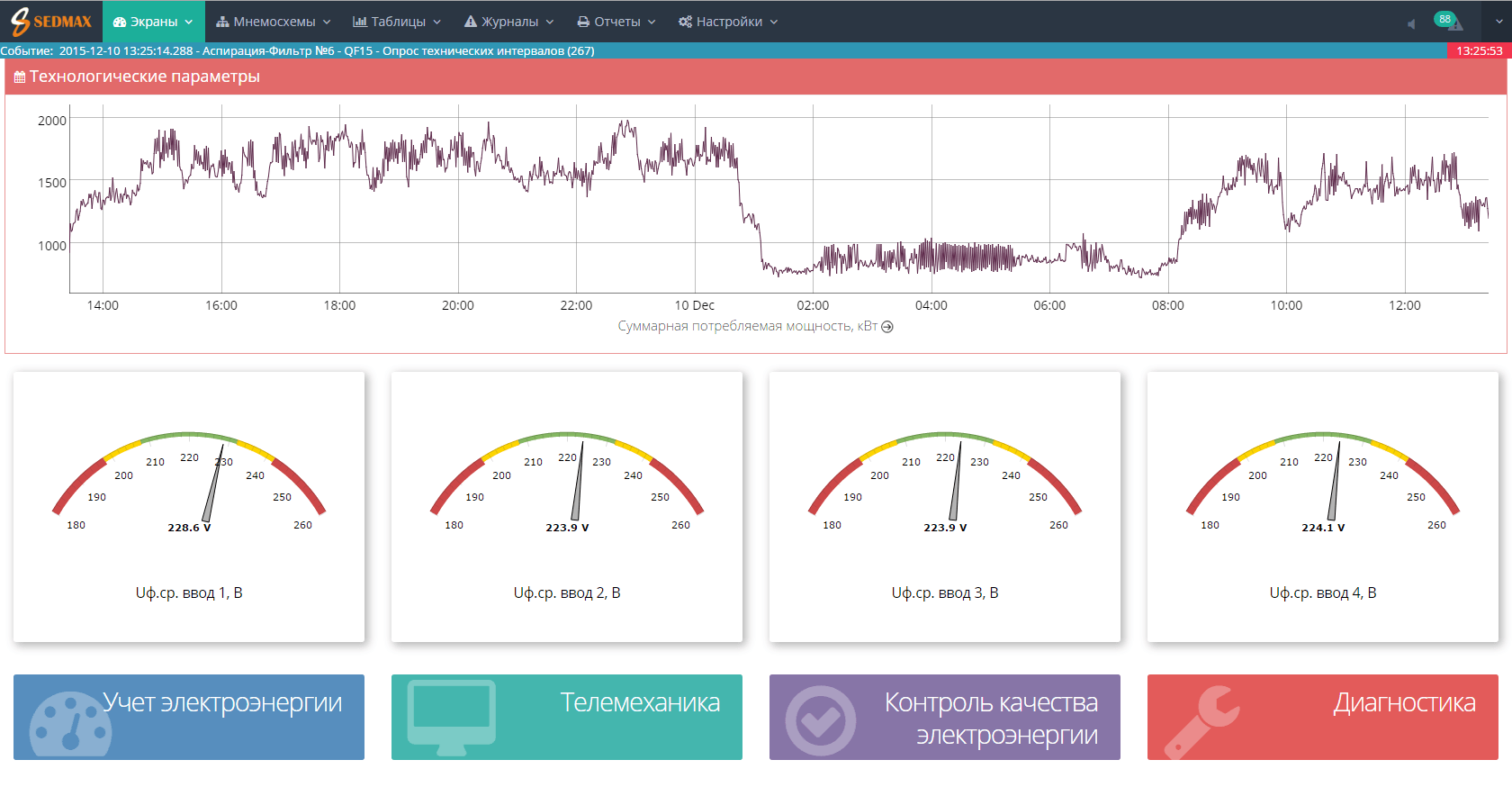

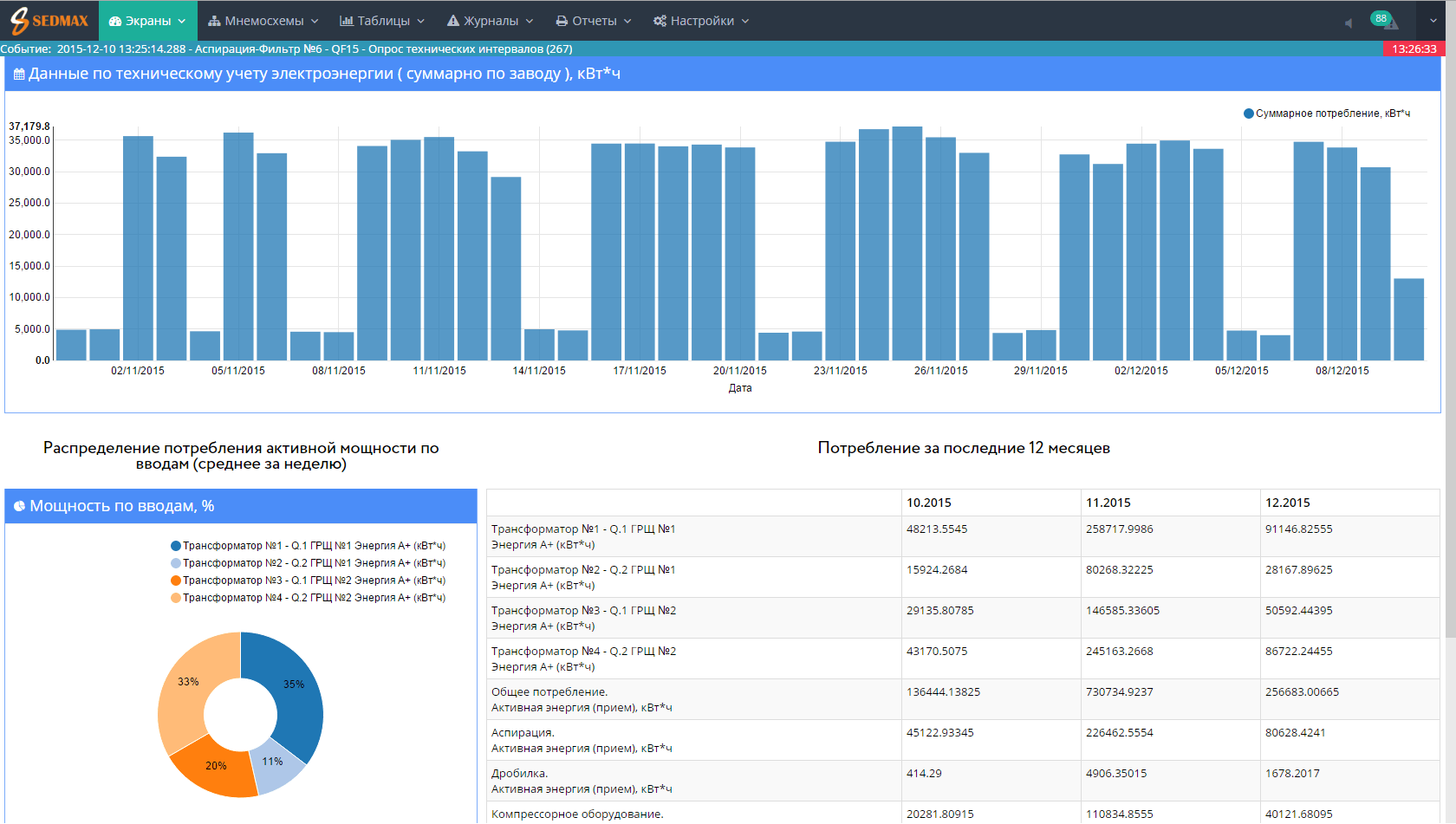

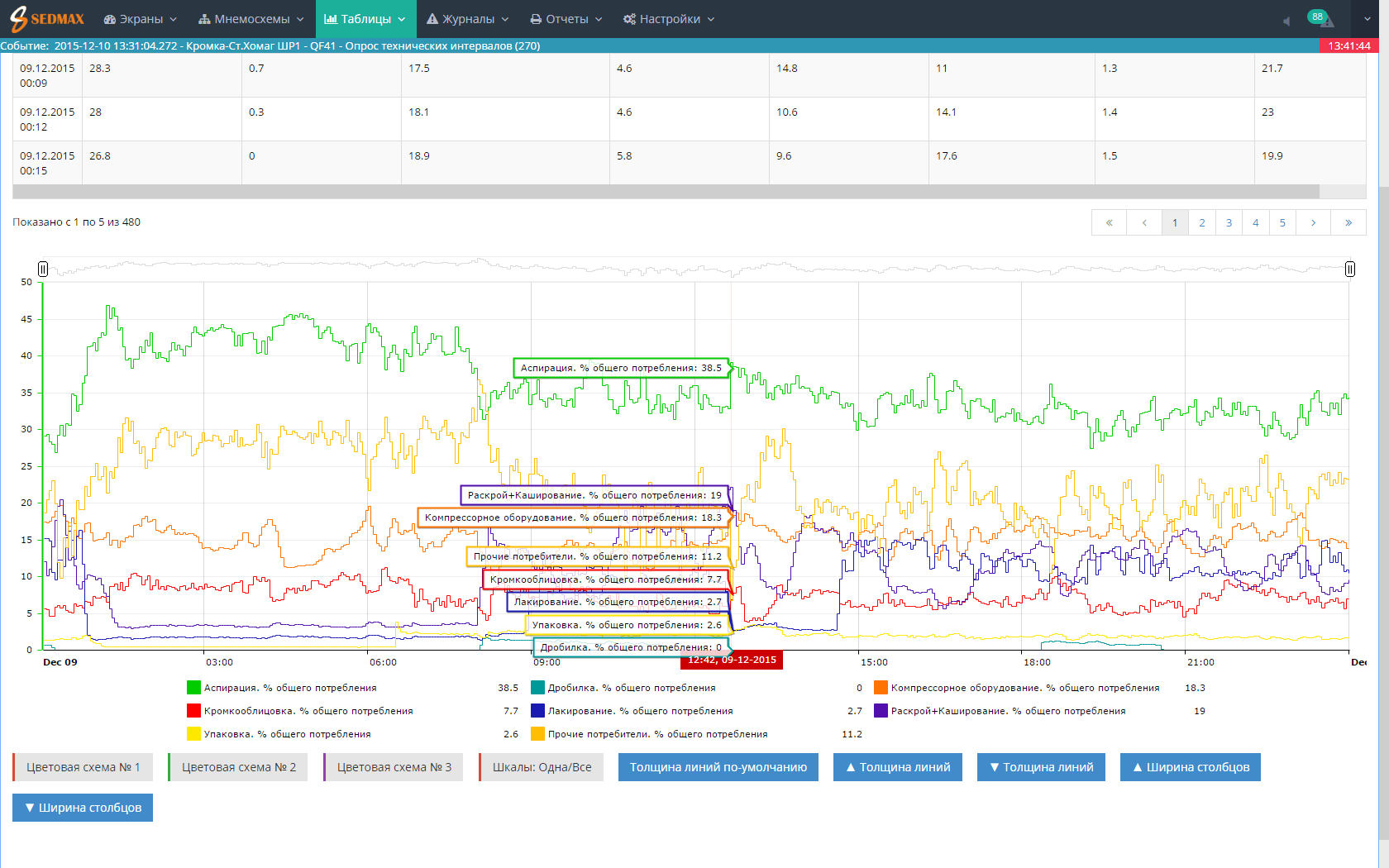

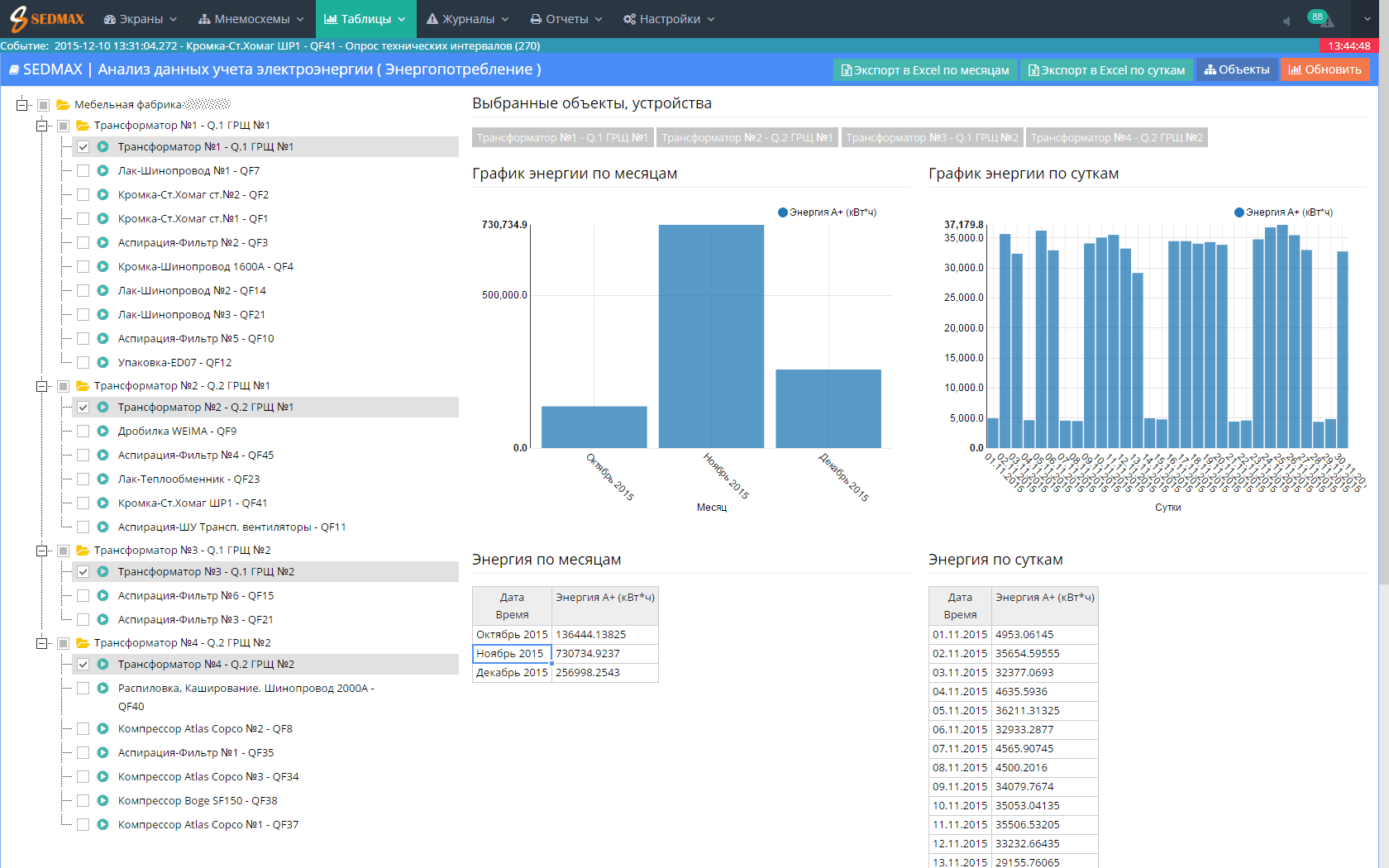

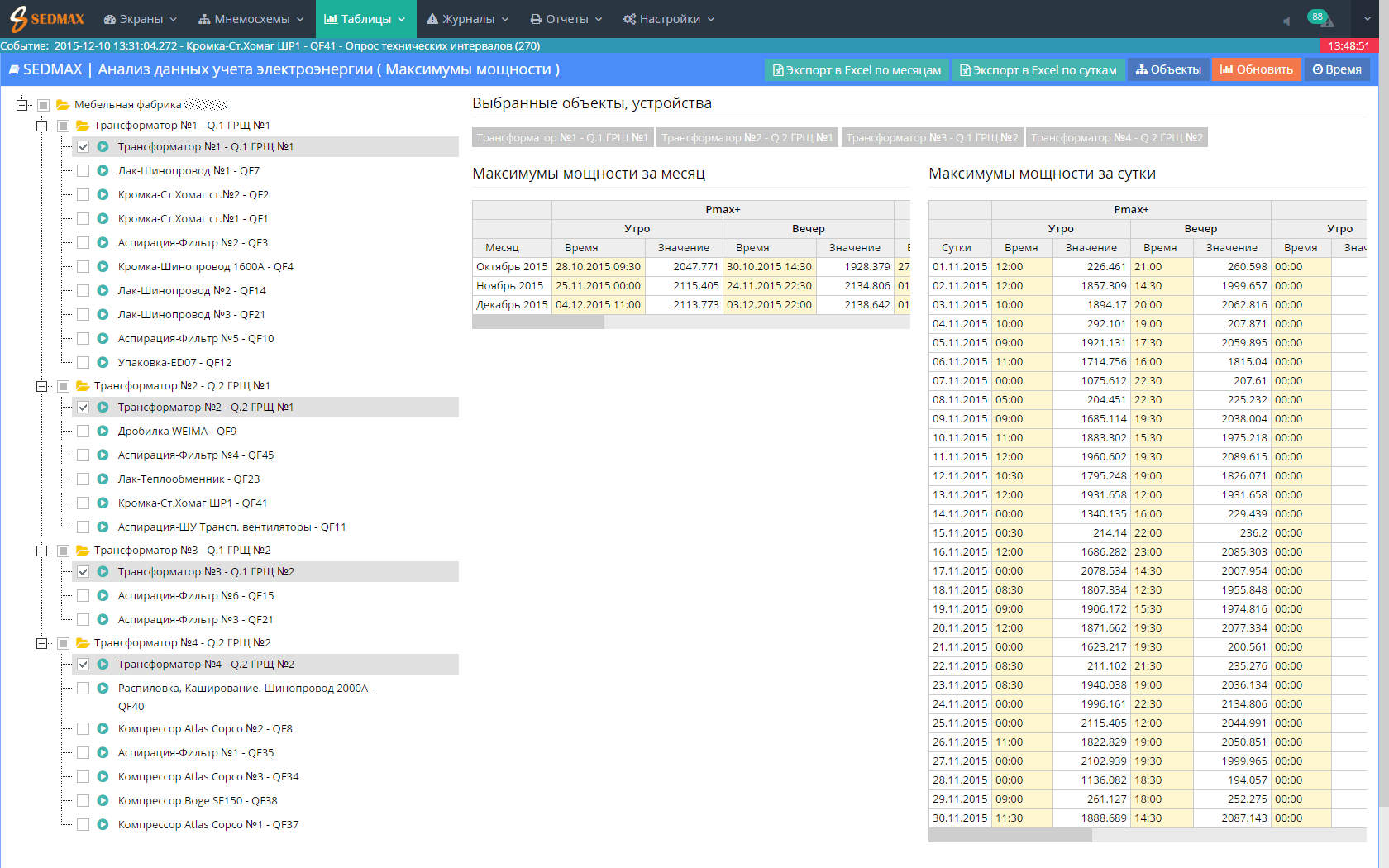

Electricity meteringSEDMAX collects tens of electricity parameters from various devices, generate reports

-

Metering of heat,

water, steam and gas flowsSEDMAX collects data from heat and flow meters, pressure and temperature sensors -

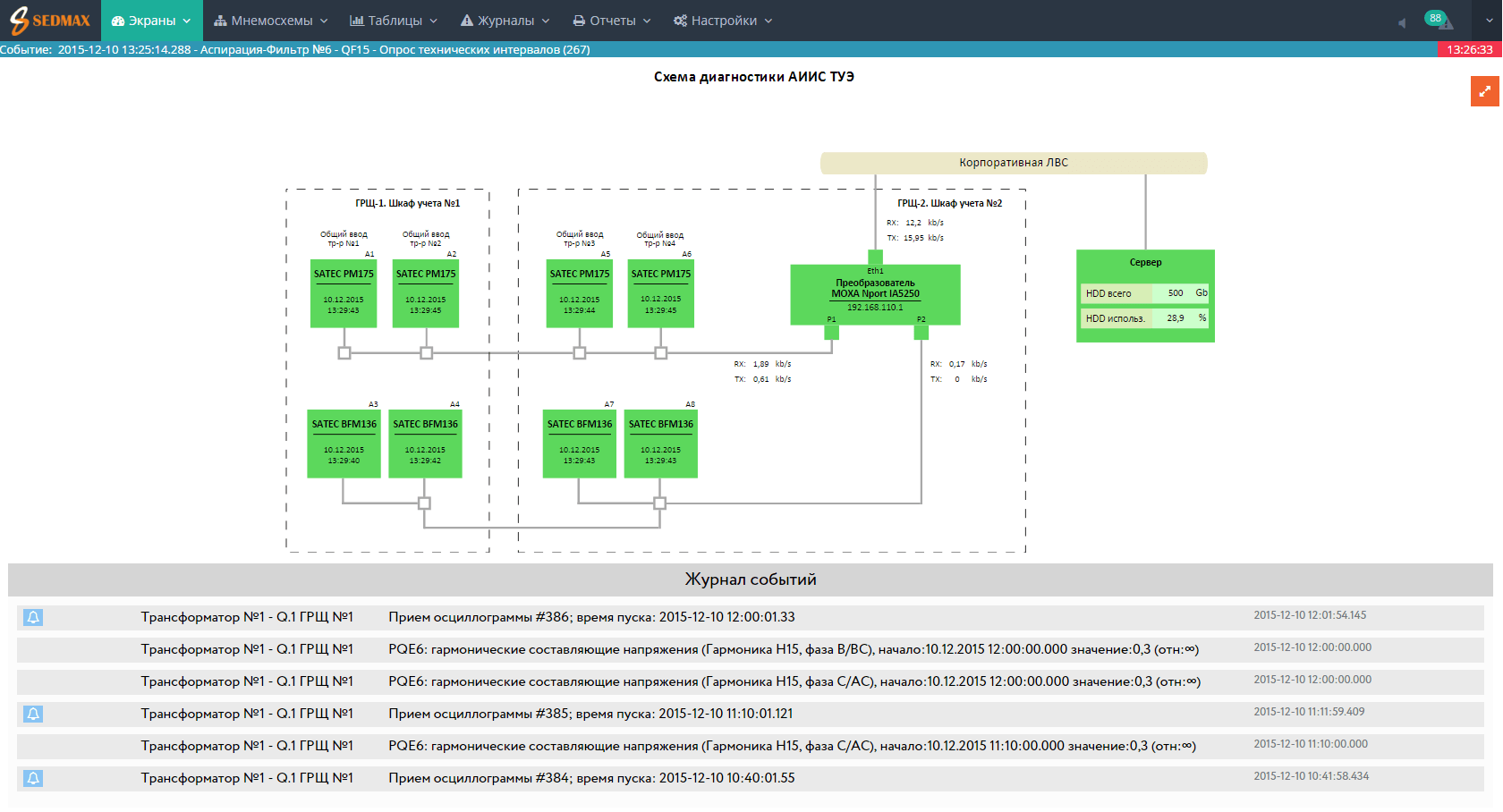

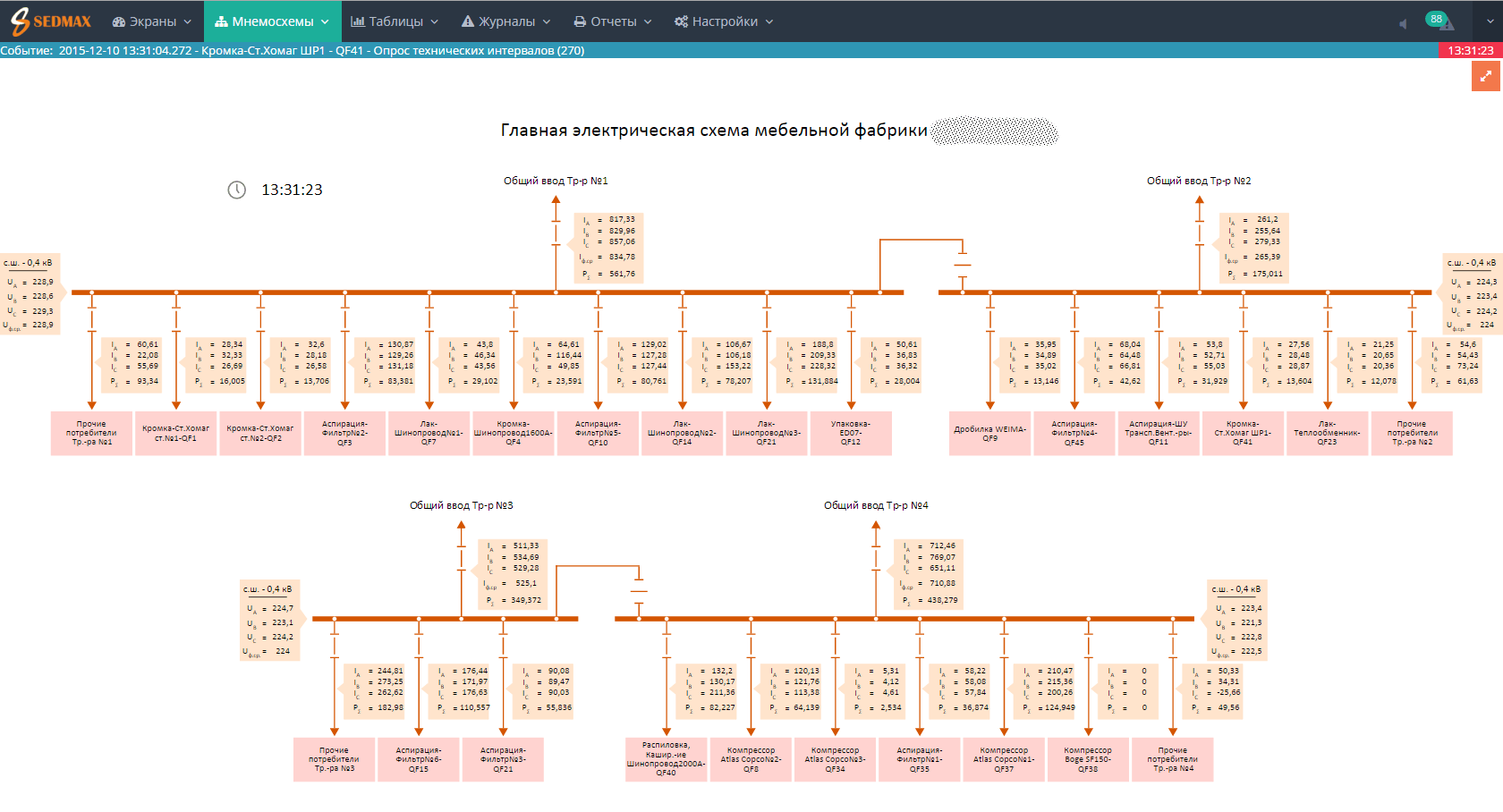

Dispatching and

monitoring of power systemsDispatching based on hundreds of thousands of indicators and metrics with high reliability due to the redundancy and clustering functions. The data collection period up to 0.1 seconds -

Monitoring of manufacturing indicatorsA single tool for real-time monitoring and management of all production processes. Work with technological data from various systems and sources to control all aspects of production

-

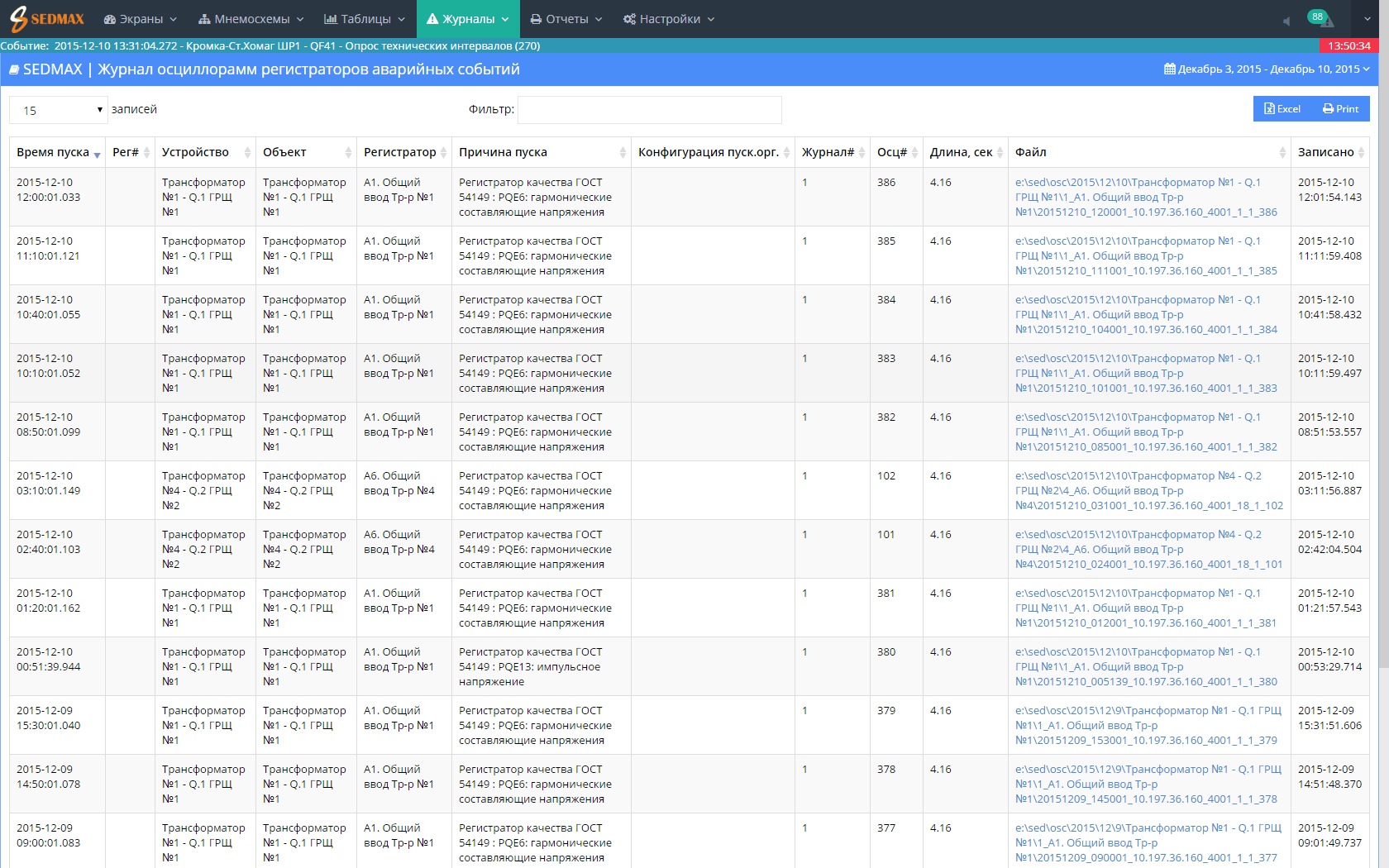

Disturbance records

collection and analysisCollection and storing of waveforms from multifunctional devices and digital relay protection units. Waveform conversion into a unified format (COMTRADE) and displaying in a single interface for further analysis with the possibility of flexible filtering. -

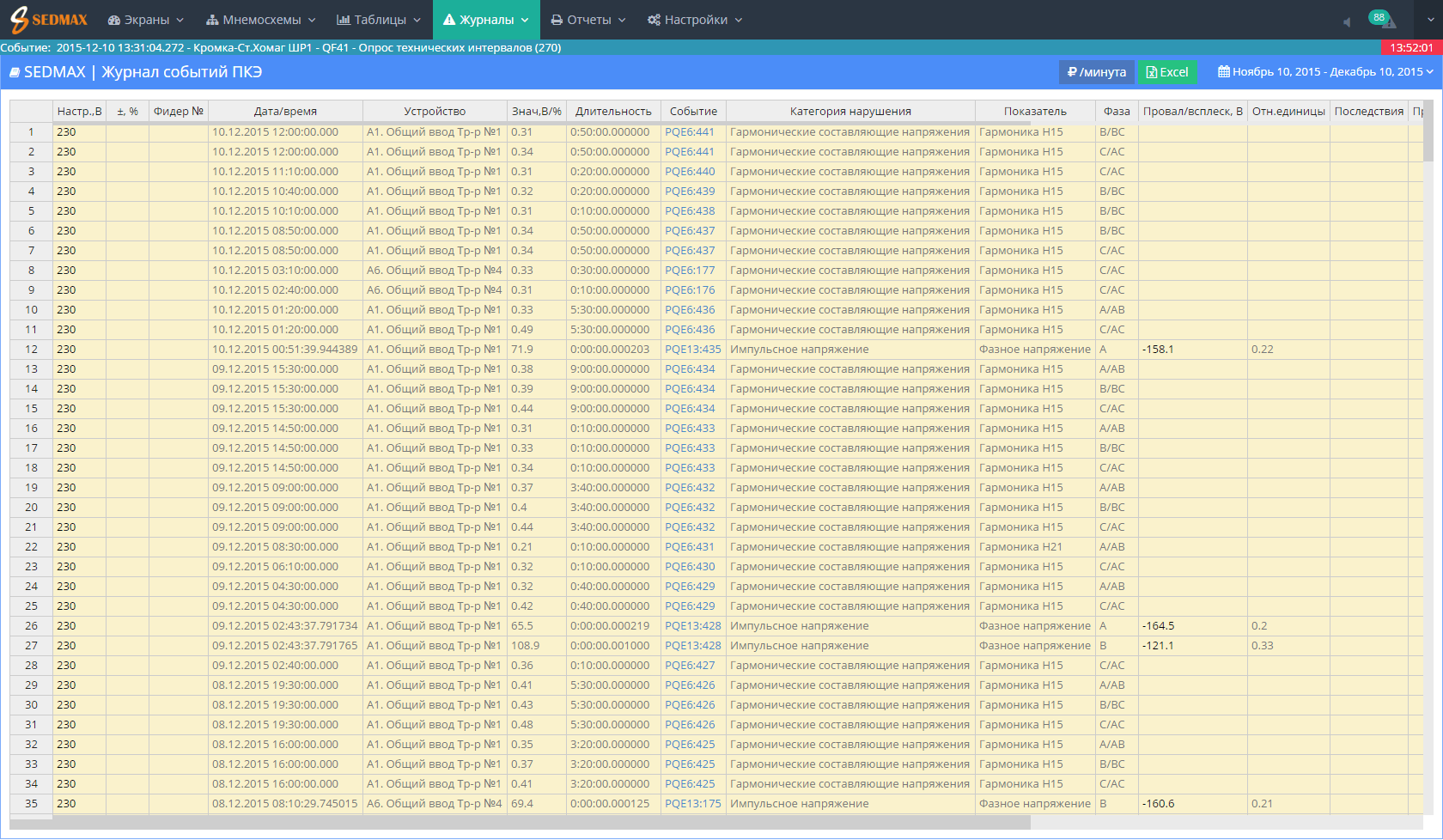

Power quality controlSEDMAX consolidates information from power quality meters to detect violations of power quality indicators and its causes and generate reports for subsequent analysis

-

Data collection and transferringSEDMAX integrates various information systems and data flows in a single environment for its subsequent transferring to external third-party systems and tools in a single stream and with a single interface.

-

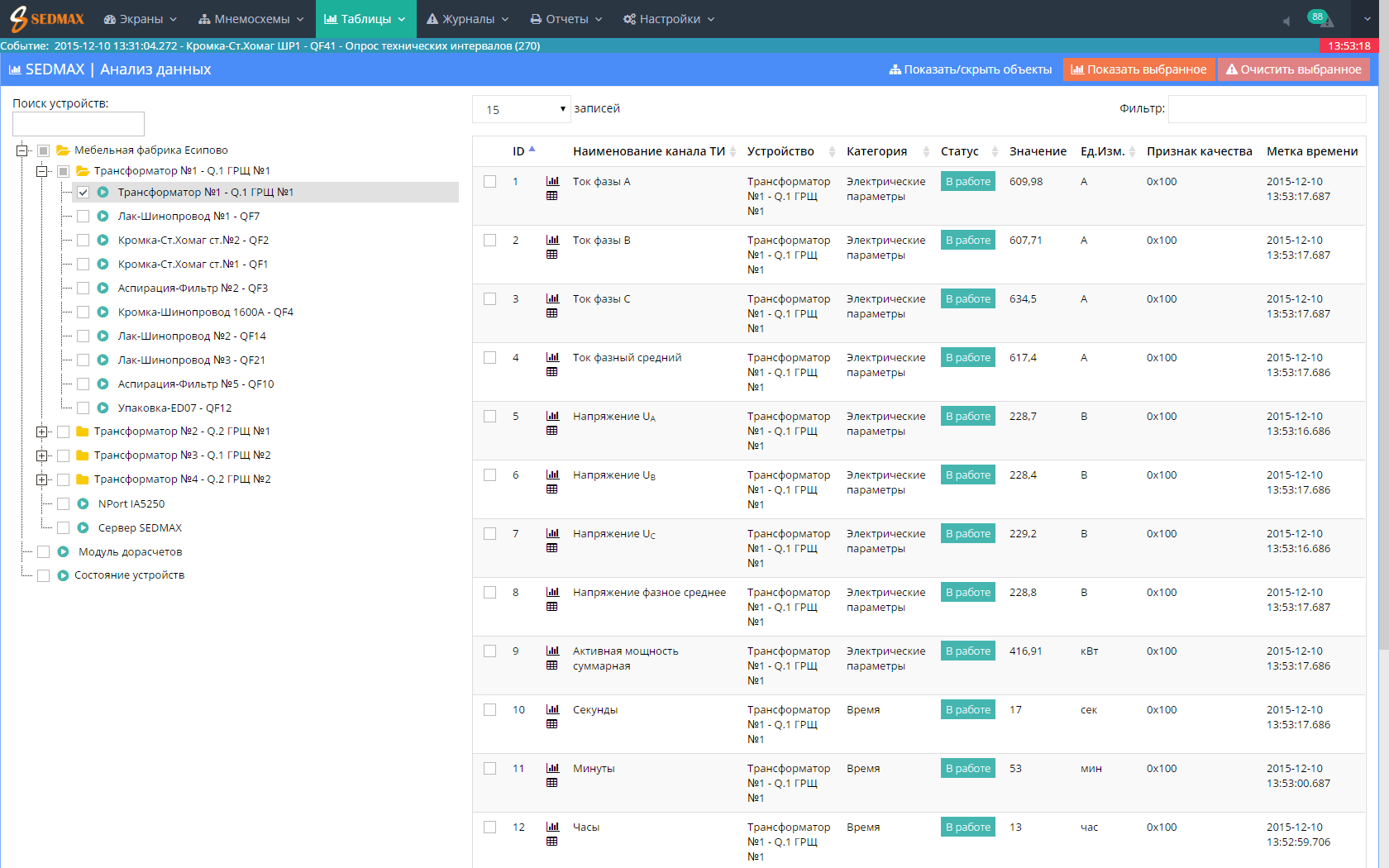

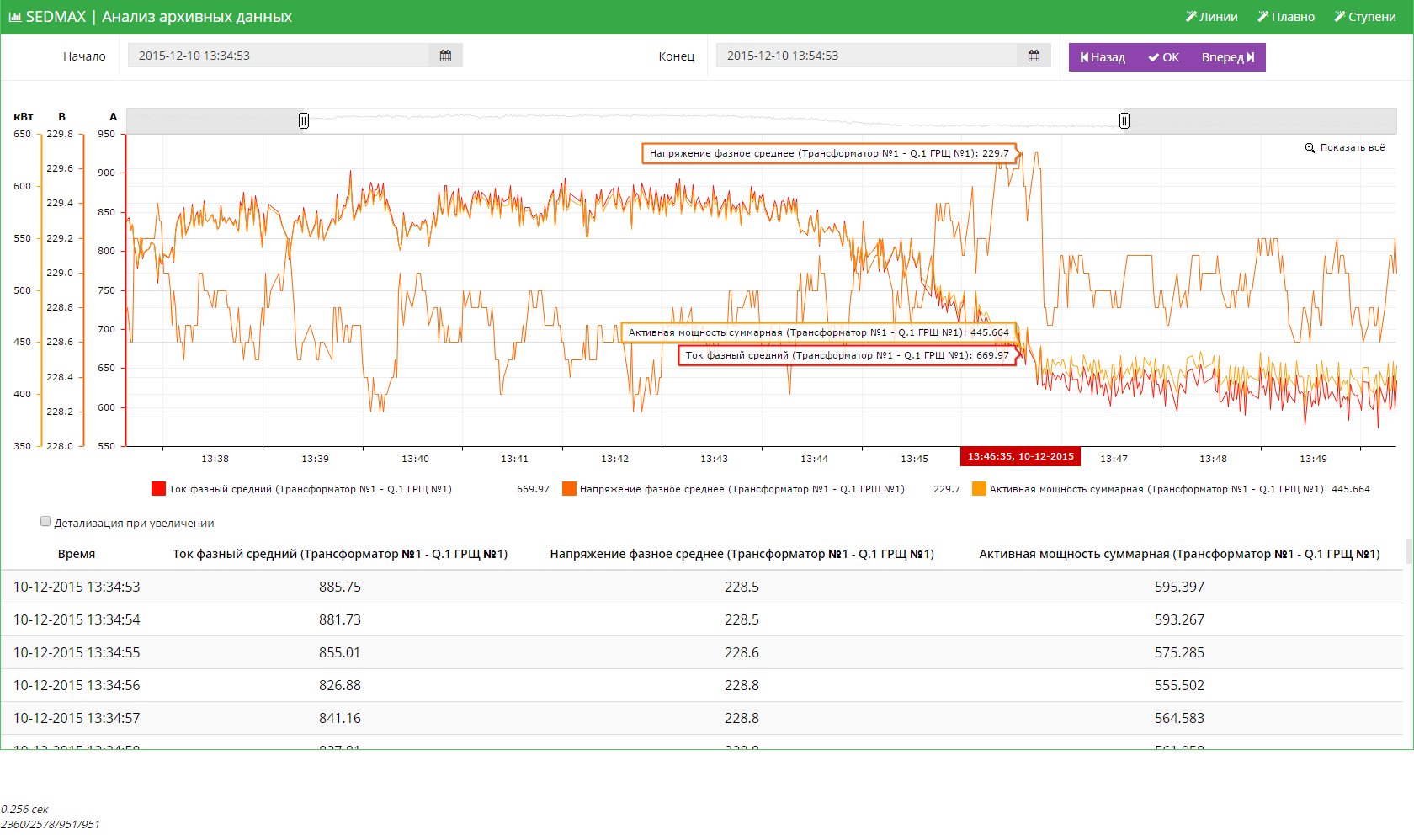

Basic data analysisSEDMAX implements data analysis algorithms to control production processes and KPIs, to optimize technical and economic indicators, to make data-driven decisions, to assess risks and make predictions.

Advantages

Customers need completed solution: take SATEC equipment, SEDMAX software and mix with your engineering expertize

01

Multifunctional equipment runs best with multifunctional software

Both SATEC and SEDMAX solve tasks of electrical staff and operators, chief power engineer and planning department.

02

Unified interface and access to all devices

As you want to know the picture of energy consumption/generation, you need SEDMAX to display, compare and analyze data from all devices

03

Write data to storage for analytics

Nowdays, building of data collection and storage infrastructure is one of the most significant tasks of industrial companies

«...at the moment, we get all necessary data to forecast our consumption, identify abnormal consumers and potential to optimize efficiency from desktop, tablet and smartphone...»

04

Alarm handling and notification

SEDMAX allows users to set up rules on notifications via e-mail, sms, etc.

05

Vector graphics for mnemonic diagrams

Mnemonic diagram is the main tool for dispatchers and operators to control in real-time and identify points of failure.

06

Flexible reporting

Use flexible reports when your need to analyze data to make better desertion or prove your idea

07

SEDMAX works with all SATEC devices and whole data types:

real-time, historical data, waveforms, logs and power quality data

Make your solution more powerful

and useful for your clients

HOw it works

Look at the stages of SEDMAX work and evaluate its main features for 2 minutes

CAses

Explore multifunctional projects

with SEDMAX software and SATEC equipment and compare with your customers situations

ABOUT US

We are engineers and developers

with 15-years experience in industrial automation

Contacts

Headquarter:

Product site:

sedmax.com

All offices

ENPRO-Northwest

VOLOGDA CITY

10 Sergey Preminin St. Vologda, Russia

+7 (8172) 26-48-14

info@sedmax.com

10 Sergey Preminin St. Vologda, Russia

ENPRO-South

NOVOCHERKASSK CITY

102, Ermaka prospekt St. Novocherkassk, Russia

+7 (8635) 22-68-56

jug@en-pro.ru

102, Ermaka prospekt St. Novocherkassk, Russia

ENPRO-Siberia

NOVOSIBIRSK CITY

35 Krasnoyarskaya St. Novosibirsk, Russia

+7 (383) 230-01-25

berdnikov@satec-global.ru

35 Krasnoyarskaya St. Novosibirsk, Russia

Mongolia

MSEL LLC

#202 Khan Bogd Residence Naadamchdin Road, 4th horoo Ulaanbaatar, Mongolia

+976 (11) 990-88-685

director@msel.mn

#202 Khan Bogd Residence Naadamchdin Road, 4th horoo Ulaanbaatar, Mongolia

Start to grow your business

Thank you for your interest in SEDMAX!

In the near future the manager will contact you.